Want to check out our tractor maintenance videos? Click here to see what we've got!

We’ve had this question come in…

After about 1 to 2 hours running my MF35 3 cyl 1960 model starts loosing oil pressure. Also if taking out the oil dipstick, exhaust gases/smoke is coming out. How can I fix this? can a good DIY man fix it without an engineer? Is it safe to continue running the tractor in this condition if topping up oil when necessary? The tractor is really running well and always starts first go, even in the coldest of winter months. L.H., United Kingdom

These Are Classic Worn Engine Symptoms

There are a couple of things going on here.

The cause of the drop in oil pressure is likely to be either a worn oil pump, worn crank shaft bearings/the crank itself, or likely a combination of the two things. As the engine gets hot the oil becomes less viscous (thinner) and so passes past the worn bearings more easily (more quickly than it should do), and then the pump (which may also be worn) cannot keep up with the demand – hence you get a drop in oil pressure.

Here’s an example of some very worn bearings…

We need to measure them against published figures. Remember to measure them across the different planes, as they are usually more worn where they have taken the force of the piston/combustion.

If you are getting exhaust gasses coming out of the oil dipstick then that is a certain sign that the cylinder bores and the pistons/rings are worn. This lets exhaust gasses down into the crankcase, into the sump and the escape route is through the dipstick.

The danger when they get really bad is that if the crankshaft bearings or big end bearings get worn through too much then they can weld and seize the engine.

Basically the engine is ready for a full rebuild. It is quite surprising that it is still starting on cold days, as the lack of compression when engines get this worn usually effects starting performance.

Can you do it yourself? You can do much of the work yourself. All the dismantling and rebuilding work you can do yourself. This is quite time consuming, so you can save a lot of money here. It depends exactly what is wrong if you will need an engineer or not.

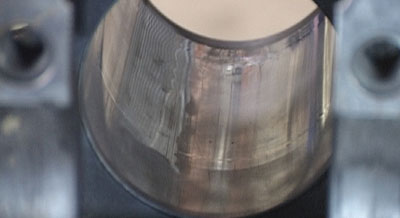

It is likely that you will need some jobs doing by an engineer. The photo below is from a four cylinder tractor, but it shows what cylinder liners should be like!!

The cylinder liners will need to be pressed out and new ones pressed in and the block may need machining to get the correct height and fit of the liners. The valves and guides is also a job for an engineer to get the best job done. The crank may also need either polishing or grinding, which is a specialist job.

Our MF35 Engine Rebuild DVD would be of use to you to assess your engine and also useful for you to see how to do all the work, including setting the tappets and the timing etc.

The symptoms of this engine really are classic characteristics of a generally worn engine.