Want to check out our tractor maintenance videos? Click here to see what we've got!

The information in this article applies equally to plain bored blocks (eg. Ford) as it does to tractor engines with replaceable liners.

The continual friction between the piston rings and the piston liners (bores) eventually causes wear to the liners. Wear also occurs because of the slight lateral force exerted on the piston from the motion of the crankshaft and connecting rod which can result in slightly oval shaped liners, as well as oval wear to the piston skirt. Other problems which result in unserviceable liners (bores) can be seized pistons due to overheating or lack of lubrication and ingress of water through the cylinder wall side (often referred to as ‘porous block syndrome’). Wet type liners can also be erroded away on the water jacket side by metallic particles floating in the coolant. These particles, which are caused by failure to continually use corrosion inhibiters (antifreeze), collect around the bottom of the liners swirling in the coolant flow, often nearest to the magnetic effect of electrical equipment, where they willl eventually abrade through the liner allowing water into the cylinder.

New liners have cross-hatched marks scored into their surface (cross-hatch honing marks) as can be seen in the picture below, where new pistons and liners have been fitted to the skimmed block of a 4 cylinder diesel MF35. As the pistons move along the bore these honing marks prevent the oil scraper ring from fully wiping all the oil from the liner, thus providing a very thin layer of lubrication to the compression piston rings.

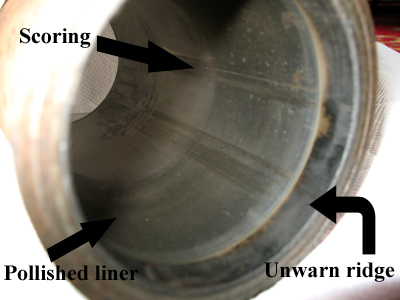

As the honing marks become smoothed off the bore size increases which slackens the fit between the piston rings and the liner, resulting in increased oil consumption and reduction in compression. This brings about an increase in the rate of breathing to the crank case and a loss of power and efficiency. The picture below is of a worn liner that is polished smooth but also has scoring along its length. Notice the ridge which has formed at the top end of the liner. This is the unworn part of the liner above where the top compression ring has not reached. If an engine has only had gentle use but is then subjected to high revs and a heavy workload, then slight stretching of the connecting rods can cause the uppermost ring to contact this ridge and cause the ring to break.

If the honing marks are either polished smooth or difficult to detect then the liner is worn and should be replaced. The honing marks should be both visible and also detectable with your fingers. Any other scratching or scoring would also necessitate replacement of the liner. Also using a bore comparator, it is possible to assess the condition of the liner in relation to the standard measurements. Measurements of liners should take place when they are fitted to the block.

[ad#2-ad-banner]