Want to check out our tractor maintenance videos? Click here to see what we've got!

When refitting a piston into a cylinder it is necessary to compress the piston rings before the piston is slid into the cylinder. To perform this operation without a piston ring compressor is very difficult and can often result in damaging the piston rings. Using a piston ring compressor is quick and easy, whilst it also ensures not to damage the piston rings.

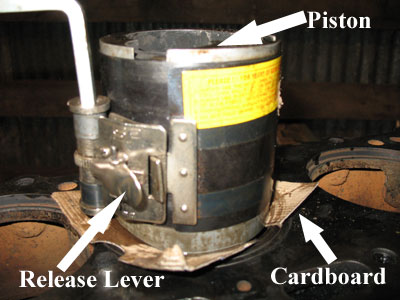

After fitting the rings to the piston, liberally oil the piston, piston rings and the inside of the piston ring compressor with engine oil. Ensure that the gaps in the piston rings are positioned in different places around the piston. Lower the connecting rod down the cylinder and sit the piston on top of the block, resting it on two pieces of stiff cardboard or similar material as shown in the picture below. Then place the piston ring compressor over the piston and tighten up, making sure that all of the rings are contained within the compressor.

Remove the pieces of cardboard and with the piston ring compressor held firmly over the cylinder, gently tap the piston into the cylinder with a piece of wood (the shaft of a wooden handled hammer is a suitable object). The piston and its’ compressed rings should slide easily into the cylinder. If the piston jams in any way, stop immediately so as not to damage the rings, withdraw the piston and try again.

When the piston is fitted, the piston ring compressor can be removed and released. Release by pushing the release lever, not by turning the screw in the opposite direction as this will damage it. Always release the compressor after use to prevent damage to the tool.

A piston ring compressor is a relatively inexpensive piece of equipment. We would recommend that anyone refitting pistons to a cylinder should use one of these tools in order to ensure that the piston rings are not damaged in any way.