Want to check out our tractor maintenance videos? Click here to see what we've got!

Firstly, because of the potential of an explosion or accidental splashing of the electrolyte, always wear safety goggles and rubber gloves. This article is specific to wet cell (flooded) lead acid batteries as they are by far the most common batteries used on tractors. Some of these batteries are termed as maintenance free (usually not possible to remove the cell caps), which are not always suitable to be recharged with a battery charger like the maintainable variety.

Most tractor batteries use lead-acid technology which contain a mix of sulphuric acid and water. A 12 volt battery has 6 cells and each produces just over 2 volts, and thus outputs around 12.7 volts when fully charged. Each cell is constructed with 6 or more plates and is designed to deliver hundreds of amps for a few seconds to start the tractor. It delivers only about 10 -15% of its total capacity and then is able to recharge quickly from the vehicle’s electric system. A charged battery stores electrical energy in the plates and has a high concentration of suplhuric acid. When energy is discharged from the plates the density and concentration of sulphuric acid drops. Water can also leave the electrolyte during discharging and so the cells need to be topped up periodically.

The rating of a battery is given by industry standards :-

- Cold Cranking Amps (CCA) – This is the number of amps a battery can output for 30 seconds at -18 Centigrade whilst maintaining 7.2 volts (12 volt battery). The higher the CCA, the better for starting – particularly in cold weather.

- Cranking Amps (CA) – This is the number of amps a battery can output for 30 seconds at 0 Centigrade whilst maintaining 1.2 volts per cell (i.e. 7.2 volts from a 6 cell 12 volt battery).

- Reserve Capacity (RC) – This is the number of minutes a fully charged 12 volt battery at 80 Farenheit will discharge 25 amps until the battery drops below 10.5 volts.

- Ampere Hours (Ah) – The time from the start to the end of discharge. For example, if a battery can deliver 5 amps for 20 hours, then its 20 hour rate is 100Ah.

The required battery specification for a given tractor is usually given by the manufacturer.

Testing

There are two common tests that can be done on a battery to assess the charge status. However, the battery must be removed from the tractor (or the terminals removed) and left idle for a minimum of 5 hours and preferably over 10 hours if it has been recharged.

Open Circuit Voltage Test

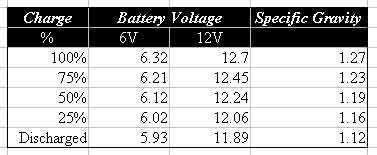

Connect a volt meter across the terminals and take a reading with no loads or charges connected to the battery. Refer to the figures below to assess the batteries’ state of charge. If it is below 75% charged, then it should be recharged.

Specific Gravity Test

Make sure the electrolyte is above the plates on all of the cells (if not, add deionised water and recharge). Withdraw electrolyte from a cell several times into the hydrometer so that the hydrometer float reaches the same temperature as the electrolyte. Then withdraw fresh electrolyte, take the reading with the hydrometer and write down the value – repeat this for each cell. Most hydrometers are calibrated for 80 Farenheit, so subtract 0.004 for each 10 Farenheit below 80 or add 0.004 for each 10 Farenheit above 80. The advantage of this test is that each cell can be tested. If variation between the cells is greater than 0.050 then this indicates damage to 1 or more of the cells and the battery needs to be replaced.

Sulphation

During normal use, material on the plate surface turns to inactive lead sulphate. Recharging breaks up this soft sulphate and renews the electrolyte. If recharging is not done regularly (about every 7-10 days), then this soft sulphate turns into harder crystals which cannot be broken up and this reduce the surface area of the plates. If simple rules are followed, then sulphation can be minimised and battery life extended for many years.

- Fully charge new batteries before use.

- Try not to deep discharge battery.

- Keep battery fully charged. Sulphation starts at anything below 90% charged, and becomes more aggressive at below 75% charged.

- Regular use is the easiest way to ensure the battery is fully charged.

- Low electrolyte level causes suplhation.

- Parasitic drain (eg. short circuit in electrical system or radio memory) causes discharging and thus sulphation.

- Keep top of battery clean and dry to prevent discharge between terminals and coat all exposed terminals, fittings and cable near the battery with anti-corrosion gel.

Basically keep your battery well maintained. Run the tractor regularly to keep the battery fully charged. If, as with many vintage tractors, it is not run weekly then regularly tricle charge the battery – solar chargers with a regulator fitted are good for this purpose, even in the winter time.

Charging

- Find a well ventilated area and keep away from sparks and naked flames.

- Don’t charge batteries which are either frozen or above 120 Farenheit.

- Remove vent caps (if possible) and top up with deionised water if necessary.

- Test with hydrometer or volt meter to determine if it needs charging.

- Re-install vent caps if applicable.

- Connect the leads with the charger unplugged.

- Plug in the charger and turn on the power whilst facing away from the battery.

- Slow charge the battery – the charger setting in amps should not be greater than 25% of the amp hour rating of the battery or 10% of the reserve capacity rating.

- Turn the charger off before disconnecting the leads.