Want to check out our tractor maintenance videos? Click here to see what we've got!

Paul has been having difficulty determining Top Dead Centre of his engine for timing purposes (or 16 degrees before TDC in the case of this engine). His flywheel does not have the standard locating hole used for this, so what can he do? Here is Paul’s question and some techniques he can use…

-

I’m currently working on a Standard 23c engine, but the flywheel does not have the hole in for finding TDC. I have, put a 1/4 in bar in the hole in the casing and turned the engine over using a socket on main pully, but the pin does not locate into a hole. Thanks for making the DVD, it is a great help. Is there anything else I can do?

Kind Regards.

-

Hi Paul,

First of all, please note the following. All designations of TDC relate to piston number 1 on its firing stroke. You therefore need to observe the valve movements to determine when the piston is at the top of its firing stroke (as opposed to its exhaust stroke). To do this observe the valve movement in relation to the piston. When piston is raising towards TDC, both valves should be closed.

The following protractor method will help you find Top Dead Centre…

There should be TopDC and BottomDC marks on the flywheel. There is also a datum mark on the back of the engine to line the marks up with. Then attach a 360 degree protractor onto the flywheel, and also make a pointer which is fixed to the engine block and points to the protractor. You are now able to take measurements in degrees of rotation.

You should only turn the engine in the direction of normal rotation, so to get to 16 deg before TDC, you should turn the engine forwards 344 degrees (you should always turn the engine in the normal direction of rotation, hence turn the engine 344 degrees forward, rather than 16 degrees backwards).

You would need to have the engine removed from the clutch housing for the above method.

If the cylinder head is removed you can use this method…

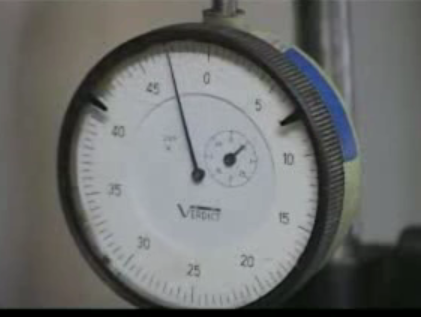

An alternative method (when the cylinder head is removed) is to use a dial test indicator to measure the position of the centre of the top of number 1 piston. The indicator will determine when the piston is at the top of its travel (TDC). You can then use the protractor method to get to 16 degrees before TDC.

Note. When the keyway in the front of the crankshaft is placed at bottom dead center, this places cylinders 1 and 4 at TDC

Hope that helps.

VTE.

Hi Grahame,

Pleased you enjoy the site.

When the engine is removed from the tractor you can see the marks on the flywheel, but obviously this isn’t possible if you are trying to do the head without removing the engine from the clutch housing. Hope your repair goes OK.

Steve.

Having just subscribed to VTE I find that having the same Standard 23C engine as PaulR and currently replacing the head gasket I will be faced with the same job of timing and valve settings that I suspect Paul is facing himself. The info provided in your latest email will be of great help to me as I hope it was to Paul. Enjoying the site immensely. Look forward to the next information forum.

Regards.