Want to check out our tractor maintenance videos? Click here to see what we've got!

Last week we took a quick look at an MF135 that was in for refurbishment. Today we take a closer look at the lubricating oil pump

This information is for the MF35 and MF135 tractors that have the Perkins A3.152 (or AD3.152) engine fitted.

How Does It Work?

The pump drive gear is pressed and keyed on to the pump drive shaft. At the other end of this shaft is a lobed rotor. This meshes with another lobed rotor which is free to turn in the pump body. So one of the lobed rotors is driving the other.

When the pump is rotating, the pockets formed between the lobes increase in volume at the inlet side of the pump, drawing in oil. The pockets between the lobes decrease in volume at the outlet side of the pump, thus pressurising and pumping the lubricating oil.

Inspection

Remove the rotors and clean up all the components. The rotors should be examined for any cracks or scoring and the pump body should be inspected for soundness.

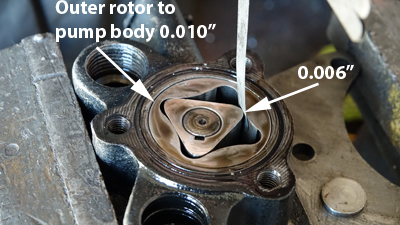

With everything clean and any foreign objects removed from the pump, the rotors should be re-installed in the pump (make sure the chamfered edge of the outer rotor enters the pump body first). Using a feeler gauge, check the clearance between the outer rotor and the pump body. This must not exceed 0.010″ to be within specification.

Next check the clearance between the maximum diameter of the inner rotor and the minimum diameter of the outer rotor (as being measured with the feeler gauge in the photograph). Undertake this measurement at all points of rotation for each lobe of the internal rotor. None of these clearances should exceed 0.006″ to be within specification.

The last check is undertaken by placing a flat and straight object such as the edge of a steel ruler across the face of the pump body (o’ring removed). There will be a small clearance between the surface of the pump body and the surface of the rotors. This should not exceed 0.003″.

The relief valve (mounted on the delivery sdie of the pump) should open at between 50-65 p.s.i.

The Take-Home

The oil pump is a very simple and a very durable piece of engineering. It is often still within specification when an engine comes in for a rebuild.

A new pump is relatively inexpensive, so many people do decide to replace the component whilst the engine is dismantled.