Want to check out our tractor maintenance videos? Click here to see what we've got!

Clutch stiffness is something which users soon complain about, particulary if there is a loader fitted to the tractor. Some models (eg. MF165) have a grease nipple on the release shaft, which would be the most obvious place to start. However, it is likely that the tractor will need to be split to access the clutch and make further investigations.

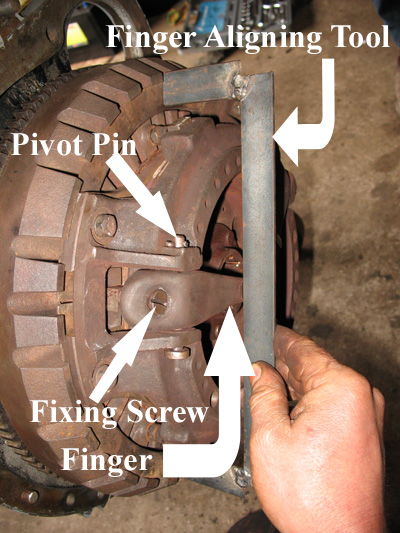

An often overlooked, yet most likely cause of clutch pedal stiffness is the condition of the clutch finger mechanism. Worn pivot pins and fixing screw heads can, and do, affect the fingers’ movement. Replacement of these parts can significantly ease the pressure required on the clutch pedal. The holes in the end of the fingers themselves (where the fixing screws fit through) are also likely to be worn and so replacement may be necessary. When these components are in need of replacement, one or more of the clutch fingers sometimes don’t fully release. This causes uneven pressure on the clutch plate which obviously affects the friction efficiency of the clutch.

The fingers must also be adjusted both correctly and evenly. If the release bearing does not contact all the fingers equally then an uneven release of the clutch mechanism can occur, causing jamming and thus stiffness back at the pedal. Adjustment of each of the fingers can be checked with a simple tool as shown in the diagram.

[ad#2-ad-banner]

I need to replace all three “fixing screws”. Where can I get new ones?

Does the performance of the lift get worse as the transmission fluid gets warm? If so then this is classic symptoms of a worn pump and a repair kit would need to be fitted.

Steve.

My 185 hydraulics are very slow at lifting I changed the oil and filter which improved the lift a little but didnt cure the problem would I need to fit a new pump?