Want to check out our tractor maintenance videos? Click here to see what we've got!

Paul has been having trouble getting a pin into the flywheel of his tractor engine to locate 16 deg before top dead centre (TDC)…..

I’m currently working on a couple of 23c and trying to find the hole in the flywheel. I have, as per dvd, put a 1/4 in bar in the hole in the casing and turned the engine over using a socket on main pully. I’ve done this quite a few times and no luck. Is it possible that it has not got a hole in it? If so, what else can I do? Cheers.

Hi Paul,

Everything is possible.

Has it got a replacement flywheel I wander? – although you would expect that to be drilled as well. Otherwise how would the factory have set it up?

So you’re trying to determine the degrees before Top Dead Centre of the flywheel.

One way to determine the crankshaft angle without using the timing hole is by the TopDC and BottomDC markings on the flywheel. Using the timing marks on the flywheel and the datum mark on the back of the engine (next to flywheel) the TDC position can be determined. Then stick a 360 degree protractor to the flywheel and make a pointer which is attached to the engine block. You now have the facility to make a measurement in degrees of rotation. You should only turn the engine in the direction of normal rotation, so to get to 16 deg before TDC, you should turn the engine forwards 344 degrees.

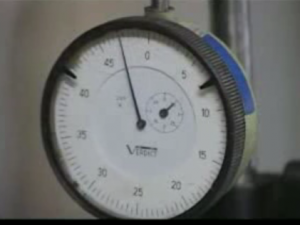

Another method of determine the postion of TDC when the cylinder head is removed is to use a dial test indicator on the centre of the top of number 1 piston. The dial test indicator will show you when the piston is at the very top (ie. TDC). Then use the protractor method (as above) from there on to get to 16 deg before TDC.

Quick note. All designations of TDC relate to piston number 1 on its firing stroke. So you need to observe the valve movements to determine when the piston is at the top of its firing stroke rather than exhaust stroke. To do this observe the valve movement in relation to the piston. So when piston is raising towards TDC, then both valves should be closed.

The above method will give the same 16 deg before TDC as the 1/4 in bar into hole in flywheel.

It will be very odd if the timing hole is not there.

Hope that helps and makes sense.

Steve + Ian VTE.

Hi Steve

Wondering why I am not receiving your news letter since the new year

We bought a masey ferguson 35 tractor. We cannot figure out the timing marks. We know the top front crank mark but not the flywheel marks. The model is in the 1950’s. Can you be of assistance?

sorry i ment tourque. plz help i need it by monday!!!!

can you tell me the cilinder head tourgue on the bolts p/p?

Hi Paul,

…you need determine when the spill cut off point is for the injector pump…

http://vintagetractorengineer.com/2009/01/timing-tractor-injection-pump-using-spill-cut-off-point/

Next turn the engine until you get to approximately 17 degrees before TDC (ever so slightly before 16). And then connect the injection pump drive to the engine. You should then be in approximately the correct position – injection pump timed to engine.

Sorry for taking so long in replying (very busy at the moment). I guess you were pacing up and down at the weekend wanting to get the engines started.

Let us know what happens, if you have any luck.

Regards,

Steve

Hi Steve,

Thanks for the advice, TDC is now sorted. There is however another complication. The injector pumps are not the standard ones as shown in the DVD and manual. I’ve checked them out and it would appear they are the ones that are fitted to the TE20. I have checked the timing of these and they should be at 32 deg before TDC on the TE20. Whereas on the 23c it is 16 deg. I’m not sure which one to use. Thanks agin for your useful advice.