Want to check out our tractor maintenance videos? Click here to see what we've got!

Oil leaking from a tractor clutch housing is a common problem. We often get asked about this and what the repair involves. The following information is based on a MF35 tractor, but the procedure is similar for many makes of tractor.

Oil entering the clutch/flywheel housing can be coming from one of two places. It is either leaking seals around the crankshaft or leaking seals where the input shaft enters the gearbox. In this tutorial we are going to look at how to replace the crankshaft rope seals.

Click Here to see the video of how to fit the rope seals.

Replacing The Seals

The tractor will require splitting and the removal of the clutch, flywheel, starter motor and adapter plate.

When it comes to fitting the new seals, the first thing here is to soak the rope seals in clean engine oil for at least an hour before attempting to fit them. This is important and is often overlooked.

After removing the old seals, make sure you get the grooves completely clean to take the new seals.

The seals supplied will be the correct length, so don’t be tempted to cut them shorter. Once the seal is placed into position use a round edged tool such as a pin punch to work the seal into its groove, keeping it protruding equally at both ends. It should protrude by approximately 0.3 – 0.5mm at each end, but don’t either stretch the seal by too much and make it protrude by more than this distance or work it too far in and not have anything protruding. You will need to apply a firm amount of pressure when working the seal in, making sure that it is fitted well into the housing.

Take some care when doing the above, as people often rush the job and end up with it leaking again.

There will also be a new gasket to fit behind where the rope seal housings fit back on.

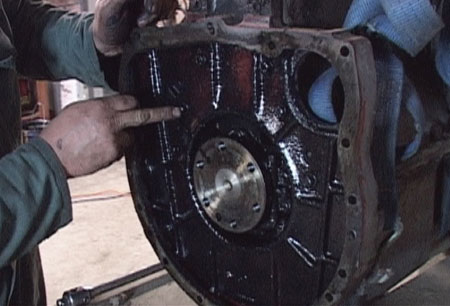

You are now ready to fit the two rope seal half housings back on. Before fitting the housings back together we would advise smearing some oil onto the crankshaft where the seals run.

Fitting the housings can take some time as it is a bit of a fiddly job. Tighten down the holding together bolts a bit at a time at each side to keep the pressure on the housing and seals equal. It may be necessary to lightly clamp the housings together in order to get the bolts started.

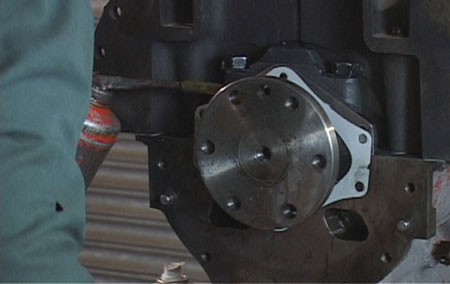

These photos were taken when we were doing the 3 Cylinder Engine Rebuild DVD, so the engine was removed from the tractor and only partially rebuilt. In normal circumstances, this task would be undertaken with the tractor split, but with the other engine components still attached and the front wheels attached.

While you are in this area of the tractor it is often sensible to replace the small spigot bearing in the centre of the flywheel. Flywheel holding bots should be tightened to 75 lbs/ft (MF35).

Both removal and re-fitting of the clutch is quite an involved process and you will need to follow the correct procedure in order to remove it safely. This is obviously a good time to assess the clutch and undertake any necessary work.