Want to check out our tractor maintenance videos? Click here to see what we've got!

We have already shown some snap-shots from the strip-down of this engine. Today’s photos from the DVD (34 of them!!!) are from the rebuild process, including the visit to the engineers. Here they are, enjoy…

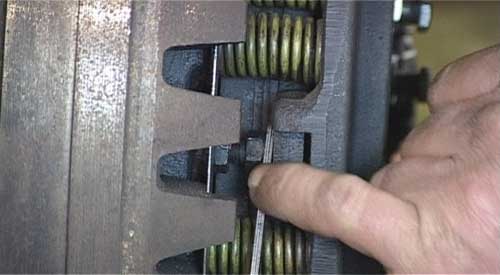

Re-cutting the valve seats to the correct angle. Valve seat inserts needed fitting as there was too much wear on the old seats for a simple re-cutting.

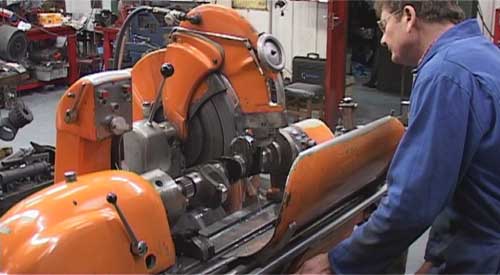

The crank grinding machine. Here the grinding wheel is dressed to get the correct corner radius for our journals.

Concentrating on the job! Grinding a crank is a skilled operation, John has done it for a long time and always makes a good job. An interesting process to watch, especially the big ends.

This machine is about to cut a new step for the cylinder liners to fit onto. The cutter self-centres, in this photo the cutting head is determining its position before it starts to cut.

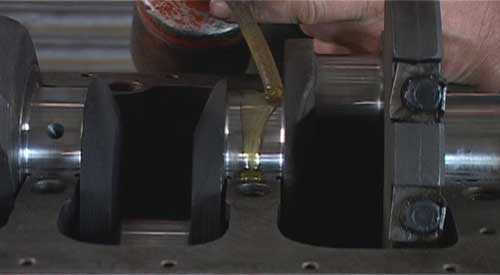

Lubricate all bearing surfaces as they are fitted together. Use clean engine oil. Note the plastic end fitted to the oil can to prevent the steel oil can from scratching the bearing surface.

Take some care when fitting the bridge or you will have trouble with sealing the sump and timing cover.

Fitting rope seals. Lots of people get this wrong and end up with oil leaking. Take care and use the correct procedure.

Looking inside the cover plate of the injection pump. The flywheel is at the spill mark before setting this.

After fitting the axles and wheels the tractor can then be let down off its stands so it is now safe to work on.

The cylinder head is assembled and then fitted back to the block. There is a specific sequence for tighteneing down the head bolts.

The wiring loom goes back on. Just a few more components to fit and then we will be ready to try and start the engine.

Make sure the oil bath air cleaner is cleaned out, fresh oil added and the element is in good condition. We don’t want to ruin all our good work.

The filters and fuel injection pump have been bled and we can see here the fuel coming out of the injector pipes. These can then be tightened down and we are ready to try starting the engine.

A few seconds of cranking and away she went. The blue smoke here in this photo will be the excess oil burning off the pistons that we used to lubricate during assembly.

I hope these snap-shots from the film go some way to showing the detail we have tried to cover in the DVD – but it is all important detail. There’s no point in doing an engine rebuild if things aren’t done properly.