Want to check out our tractor maintenance videos? Click here to see what we've got!

Here we are going to look at tractor oil bath air filters. How they work, what oil to use and the maintenance of the oil bath filter in your tracor.

How They Work

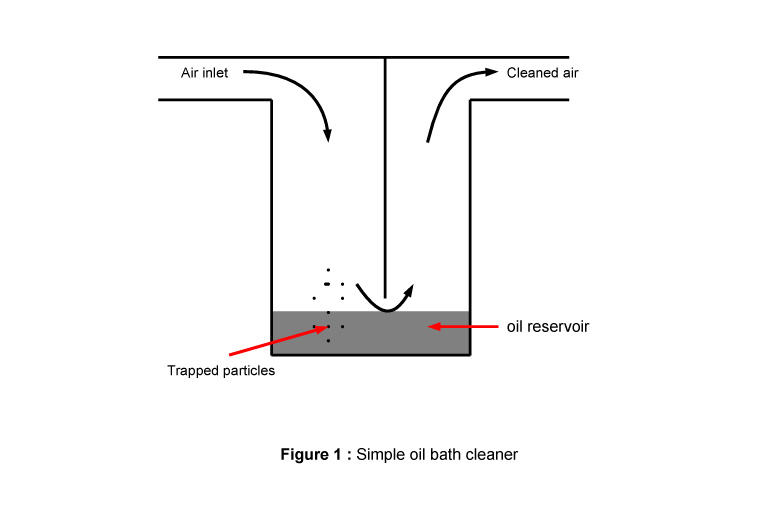

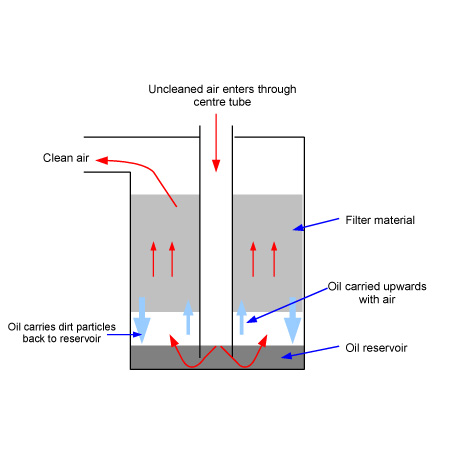

The general principal of an oil bath air cleaner is that incoming air is sucked downwards through the system towards a bowl containing a reservoir of oil. Figure 1 shows how the airflow has to make an abrupt change in direction from travelling downwards towards the oil pool before then heading back upwards to the filter outlet. The air changes direction easily, however any dirt carried in the air is unable to make the turn due to its inertia so it continues straight on into the oil where it is trapped. This system is considered satisfactory for engines which are generally working in clean air environments such as cars Tractor engines work in dusty conditions and so the majority of manufacturers have progressed this principle to make it even more efficient at capturing the last remaining particles of dirt. The bottom of the air inlet pipe is submursed below the oil level so that the air must pass through the oil (Figure 2). At this stage the larger particles are captured by a combination of the inertia principle as detailed above and by centrifugal force created within the oil reservoir. As the air heads back upwards under suction through the filter it now must pass through a packing material (fibre, mesh, foam or metal shavings). The air carries with it some oil up into the packing material where smaller dust particles become trapped and the cleaned air continues upwards and out of the air cleaner. The process of the air carrying oil with it up into the packing material has the effect of washing the dirt particles back down into the reservoir.

Tractor engines work in dusty conditions and so the majority of manufacturers have progressed this principle to make it even more efficient at capturing the last remaining particles of dirt. The bottom of the air inlet pipe is submursed below the oil level so that the air must pass through the oil (Figure 2). At this stage the larger particles are captured by a combination of the inertia principle as detailed above and by centrifugal force created within the oil reservoir. As the air heads back upwards under suction through the filter it now must pass through a packing material (fibre, mesh, foam or metal shavings). The air carries with it some oil up into the packing material where smaller dust particles become trapped and the cleaned air continues upwards and out of the air cleaner. The process of the air carrying oil with it up into the packing material has the effect of washing the dirt particles back down into the reservoir.

Oil bath air cleaners have been largely replaced by dry paper filters in most modern tractors, as the oil makes servicing both messy and inconvenient due to the frequency of cleaning required. Oil bath filters are, however, very efficient at capturing dirt and can sequest a large amount of dirt relative to their size, without loss of efficiency. They are probably more efficient at providing clean air to your engine than modern paper filters.

Oil bath air cleaners have been largely replaced by dry paper filters in most modern tractors, as the oil makes servicing both messy and inconvenient due to the frequency of cleaning required. Oil bath filters are, however, very efficient at capturing dirt and can sequest a large amount of dirt relative to their size, without loss of efficiency. They are probably more efficient at providing clean air to your engine than modern paper filters.

Servicing and Troubleshooting

Dirty oil will not be able to wash the particles down from the packing material. The reservoir should be cleaned and filled with new oil each day or twice daily in dusty conditions. Be sure to remove all the sludge from the bottom of the reservoir.

Use the correct grade (weight) of oil. If the oil is too heavy it will not be carried up by the air onto the packing material. Conversely, if the oil is either too light or the reservoir is too full then oil can be carried through the packing material and towards the engine. In petrol fuelled models this can enrich the fuel mixture in the carburettor and not only increase exhaust emissions of unburned hydrocarbons but also increase fuel consumption. Inspect the inside of the clean pipe for any traces of oil. If you cannot find the specification for the oil then as a general rule your system will usually be designed to use the same type of oil as the lubricating oil in the engine. In very cold conditions it may be necessary to use a lighter oil or dilute the oil with up to 25% paraffin to manipulate the oil viscosity.

Hoses must be in good condition as the filter on your tractor will be engineered for the air volume and velocity created by your engine; cracked hoses will create differences in operating pressures.

Comments….

1

The Vintage Tractor Engineer says:March 25th, 2008 at 5:19 am

The design of the air filter is slightly different for the petrol engine compared with the diesel engine. However, the principal is the same and they both just rely on the use of the wire mesh and the oil.MF recommend that the air cleaner should be cleaned every 8 hours (or even twice a day in dusty contitions) – it will also help if the tractor has the air intake protruding above the bonet.

I do not know many people who clean their air filter every 8 hours, but doing so will prolong the life of the engine. The oil should be changed, using the same grade as the engine oil. In very cold weather it is permissible to add up to 25% paraffin so that the oil flows freely.

Hopefully your wire mesh should be in sound condition. If so, you can clean the entire unit occasionally using paraffin. Afterwards, the element should be thoroughly dried out with an air jet.

The petrol engines tend to be fitted with one wire mesh which is in the main body of the filter. The diesel engines tend to be fitted with one wire mesh in the main body of the filter and another detachable one in the lower

(removable bowl) part of the filter, just above the oil reservoir.Hope that gives you some useful information.

2

Bob McCurry says:June 17th, 2008 at 2:58 pm

where can I get a gasket for my JD 710 ag tractor’s oil bath air filter? No parts are available in the US or Canada. this is a tractor made in Germany, sold in Europe and Canada.3

The Vintage Tractor Engineer says:June 17th, 2008 at 7:08 pm

Hi Bob,John Deere have an online parts search website…

https://jdparts.deere.com/servlet/com.deere.u90.jdparts.view.publicservlets.HomeUnsigned

….Otherwise, I guess your best option may be to try a JD dealer in the UK

such as RBM…..http://www.rbmagricultural.co.uk/

….they may be able to find the part for you and ship it over.

Hope you are able to source the part.

Regards,

Steve

I am trying to remove the gauze from a ted20 air cleaner without success.It looks as if the centre tube should slide down out of the body of the cleaner, giving access to the gauze. but appears to be seized/fixed at the top. Does any one have experience of removing the gauze?

I have a ferguson 30 that is leaking oil from the air cleaner bowl. Why would it do this and how can I fix it?

what weight oil should i use for the bath oil?

I have a TED20 that I’m trying to fix up. I found the top part of an oil bath air cleaner in a junk yard, but am missing the bottom cup. The diameter of the top part is about 11.7 cm or about 4.6 inches. Does anyone know the rest of the dimensions for the cup – for example the depth of the cup and the dimensions of the inner cup? I may try to improvise, but I need the dimensions. Or does anyone have any suggestions as to where to find one?

i have a ford 4000 and it has a Donaldson pre cleaner which swirls the air idea being the fine dust is spun into the pre cleaner and the swirling air continues down the pipe into the filter which is an oil bath most paper filters also have a pre cleaner no filter will trap all the dirt as a motor wouldn’t run it would starve for air.

P.S. the swirling air also increases fuel economy and power on a diesel engine.

If you ever doubt the effectiveness of an oil bath, plumb one in before a paper filter air cleaner. I did and the paper filter was clean and white for over 4 years. Did not need any formulas to tell me they are/where the best.

can i replace a broken air cleaner assembly unit from an oliver-cbt tractor with a unit for a ford with similiar horsepower?

Hi Dave,

What was the answer to your question about which compartments to fill?

I have the same question on my MF 135.

Can anybody provide some authentic data for the following:-

– Whether Dry Air cleaner is recommended for Turbo charge Diesel Engine ?

– Advantage /Disadvantage of Dry AirCleaner vs Wet AirCleaner for Turbo charge Diesel Engine.

– Selection of Dry or Wet Air cleaner for the off road vehicle at very dusty condition.

I found this page while looking for info on oil bath filter setups,i had watched an tv show where they stated that the only cars that stayed running after a volcano erupted in the pacific NW were vehicles with oil bath filters,the rest siezed up and needed new engines.Ron Sa,so i guess knothing works?i ride ORV,S and have used K@N type filters and UNI type foam filters,im not sure how they would work versus volcanic dust.

I have a 6000 or 7000 series Ford gasoline tractor not really sure of the exact model. Any ideas how to clean the oil bath filter and the weight oil I should use.

Hi,

I’m looking for a complete new ferguson tef20 oil bath air cleaner and i dont know where i can find it in the UK. Can anyone help me about that ?

Many thanks,

Fran from France

It is a myth that oil bath air cleaners are highly effective in removing FINE dust from air—the type of dust that we see hanging in the air and gets sucked into the engine’s inlet. Oil bath air cleaners are about as effective as seining minnows using hog wire fence. How do I explain this without 10 pages of technical formulas and explaniations why fine dust cannot travel rapidly from the center of an air bubble to the spherical surface of an air bubble even under several Gs of inertia force? The air bubble traveling thru oil only contacts the oil at the bubble’s surface. Fine dust away from the surface of the bubble escapes capture in the oil resevoir which amounts to about 90% of the fine dust within the bubble escaping capture. So what does the wire mesh accompolish? Very little. Air traveling past the wire mesh’s surfaces creates a boundary layer which has a similiar affect to having a glove on your hand. When passing thru the wire mesh, only a small percentage of the air’s volume gets used as boundary layer. Most of the dust-filled air passes thru the short length of wire mesh with out contacting any oil on the wire mesh’s surface. If the length of wire mesh was say 20 feet instead of a few inches, a lot of the dust would get trapped. Inside the engine, most of the dust in the air exits thru the exhaust but some of the dust contacts the oil on the cylinder wall. This dust acts like a lapping compound that wears out the sleeve and rings. It eventually shows up as crud inside the engine or as the black color of the oil.

Can anyone tell me the correct level off the oil in the air cleaner on the MF35?

Also when you remove the resevoir there are two compartments should these both have oil in them?

I have just been looking at my oil bath air filter fitted to a MF35 diesel tractor. I should have been changing the oil and cleaning the filter reguarly but was ignorant of the need, which has caused starting to be very difficult as the engine needs a squirt of either and the blocked filter is not allowing it to get through to the inlest manifold. Also it is being starved of air because of the lack of air flow through the filter.

My type of filter does not allow the removal of the wire mesh element out of the housing, the whole thing needs to be removed and washed with parafin or petrol and the bottom oil bath needs to be spotless clean before topping with clean oil. Now I shall clean it out and replace the oil regularly.

[…] they make a scan for you Cheers Peter …found this, some information about oil bath filters Oil Bath Air Cleaners For Tractors | Vintage Tractor Engineer __________________ BJ43/1980 OEM Softop ~ FJ45 LPB/1973…. old school ….endangered species ~ […]

So how do Iclean the “filter material”? When I remove the oil bowl and look up into the screen/filter material I see a lot of weeds/seeds/matter.

Thanks.

Nic